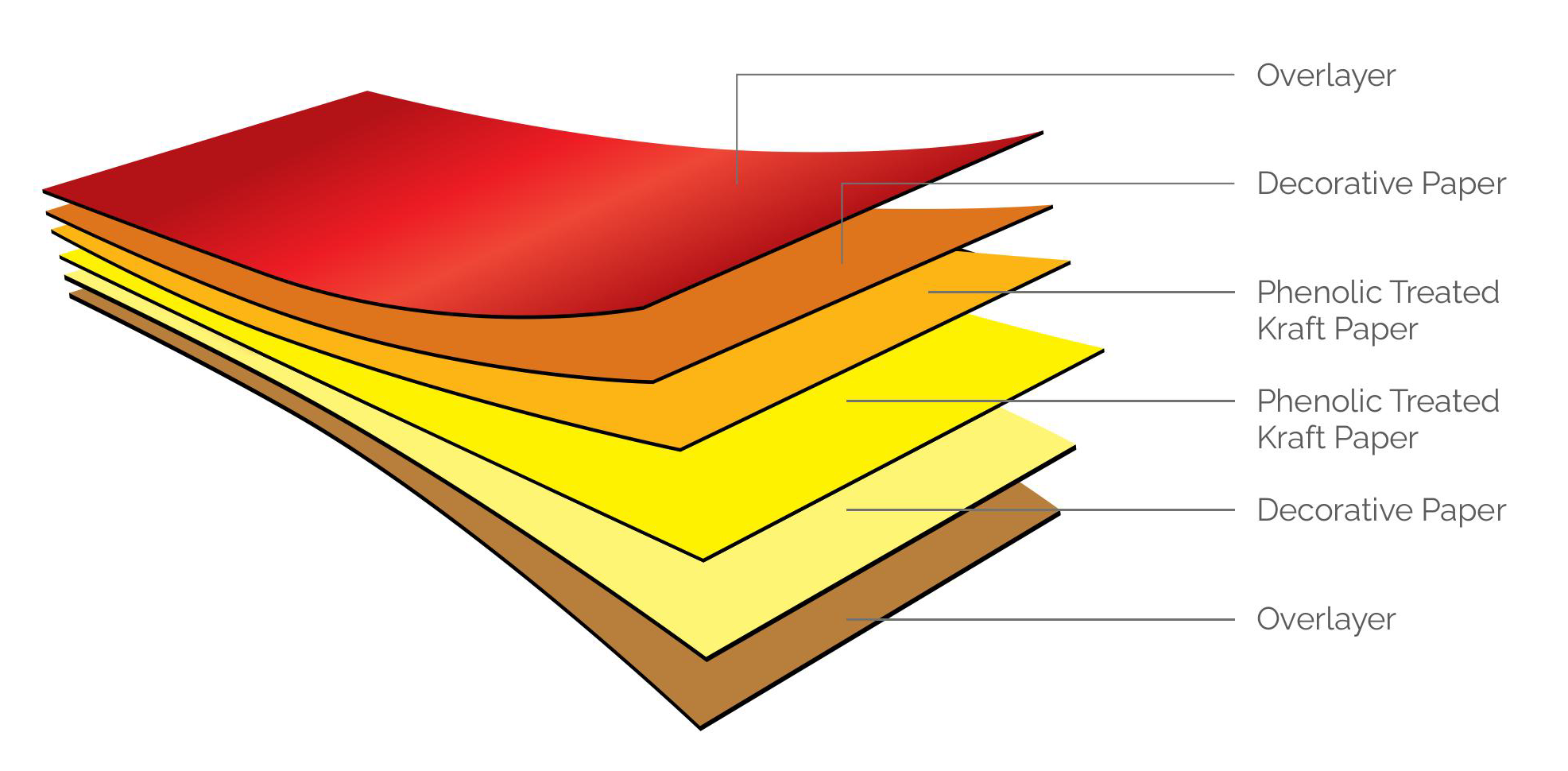

The Laminate is solid and compact (Phenolic core board) consisting of layers of cellulose fibrous material (usually paper) impregnated with thermosetting resins and bonded together by high pressure processes. The surfaces on both sides, having decorative colours or designs, are impregnated with melamine based resins. The core layers are impregnated with phenolic based resins. The high pressure process is defined as the simultaneous application of heat (temperature >120ºC) and high specific pressure (>5 MPA), to help in flowing and subsequent curing of the thermosetting resins. This is done to obtain a homogeneous non-porous material with increased density (>1350 kg/m3) and with the required surface finish. The board is manufactured as per EN-438/IS2048 Standard.

Compact panels are resistant to bacteria are also available with enhanced anti-bacterial properties with the name ‘AB+’, therefor it has antibacterial properties. These are ideal for toilets made for nursing homes, pathological labs, medical research facilities, hospitals and also in areas where bacteria can spread rapidly like gyms, swimming pools etc.

These compact sheets are built from multiple layers of high-quality kraft paper, impregnated with thermosetting resins and compressed under high pressure, offering exceptional strength and durability.

Scan the QR to call